Search This Blog

Tuesday, October 18, 2022

AT FIRST MY GAS IS BURNING BUT THEN STOP PRODUCING. WHY?

WHY MY GAS IS NOT BURNING?

Saturday, August 13, 2022

Biogas Digester Simple Design

Wednesday, July 20, 2022

Biogas Bag for Storage

Thursday, April 21, 2022

Vertical Biogas DIgester Design

Source: Joel Canaria

Observe a typical design of a digester.

Inlet - feeding occurs here having the largest diameter among all.

Gas outlet - biogas produced from the process goes out thru here connected to external storage.

Overflow - where slurry displaced by a new feeding goes out thru here.

Stirrer - to make sure agitation takes place. Optional for some practitioner.

Drain - to let the accumulated sediment to flow out thru to be discarded after operating for sometime.

Friday, April 15, 2022

Horizontal Biogas Digester Design

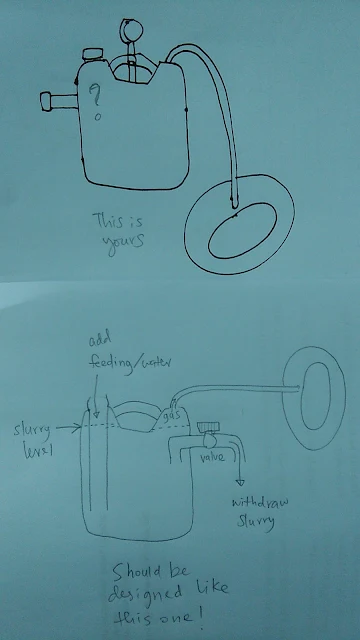

I would like you to check out this design from a friend, more details please check under the QR code. Usually the blue tank converted as biodigester in a vertical form. This is quite different which someone could try on horizontically.

Source: Jørgen Rasmussen (A Clean New World)

Or for more explanation please refer to below video:

Floating drum system for biogas storage

The system consist of two components:

1. The floating drum that has inlet and outlet for biogas. Inlet will let the biogas into the drum to be stored. Outlet is to let the biogas out when it is needed so should there be valve installed to control the process.

2. The base drum that contained water act as a platform for upper drum to float when there is gas produced. A steel guide installed to make sure the floating drum won't fall to the side.

So both drums are of different volume

a. floating drum is 160 liter

b. base drum is 200 liter

source: Biogas DIY FB Group