Ever wondered if you could turn your kitchen scraps into free energy? Well, you can! A DIY biogas system is a simple and effective way to recycle food waste while producing biogas, which can be used for cooking, heating, or even generating electricity. Plus, it’s a great way to reduce landfill waste and help the environment. If you’re beginner and curious about how it works and how to build your own, this guide is for you!

What is Biogas?

Biogas is a mixture of gases, mainly methane (CH4) and carbon dioxide (CO2), that forms when organic materials like food waste break down in an environment with no oxygen. This process is called anaerobic digestion, and it happens naturally in landfills, swamps, and even in animal stomachs! By capturing and using this gas, you turn waste into something useful instead of letting it escape into the air as pollution.

How Does a Biogas System Work?

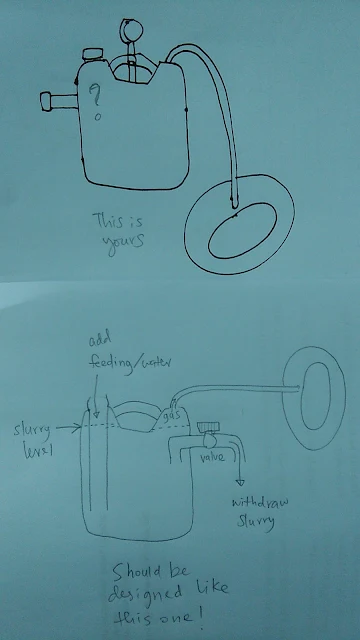

A DIY biogas system consists of a few key parts:

- Digester Tank or Biodigester – This is where food waste goes. Bacteria break it down and produce biogas.

- Gas Storage – The produced biogas needs to be stored in an expandable container like a drum or bag.

- Piping System – Tubes transport the gas to where you’ll use it.

- Outlet for Slurry – The leftover liquid (digestate) is a great organic fertilizer for plants!

The process is simple:

- You add food scraps and water into the digester.

- Bacteria inside break down the waste and release biogas.

- The gas gets stored and can be used for cooking or heating.

- The remaining liquid (digestate) can be used as fertilizer.

What Can You Put in a Biogas System?

✅ Good Materials:

- Vegetable and fruit scraps

- Cooked rice, bread, and pasta

- Leftover food (without too much oil or chemicals)

- Cow, goat, or poultry manure (helps speed up the process)

❌ Avoid These:

- Meat and bones (they take too long to break down)

- Too much oil or fat (slows down digestion)

- Chemical-based cleaners or detergents (kills bacteria)

How to Build a Simple DIY Biogas System

What You’ll Need:

- A large plastic drum (about 100-200 liters) with a tightly sealed lid (for the digester)

- A smaller container (for gas storage)

- A PVC pipe and rubber hose for gas transport

- A one-way valve (to prevent gas from going back into the system)

- A tap or outlet for the digestate

- A mixture of cow manure and water (to kickstart the bacteria activity)

Step-by-Step Guide:

- Prepare the Digester Tank

- Drill a hole in the lid and attach a PVC pipe for gas outlet.

- Install another outlet near the bottom for the digestate.

Set Up Gas Storage

- Use an expandable drum or bag to collect the gas.

- Connect it to the digester using a hose and a one-way valve.

Start the Digestion Process

- Add a mix of cow manure and water first (this introduces bacteria).

- Let it sit for a few days in a warm place.

- Start adding food scraps daily.

Monitor Gas Production

- After a few weeks, you should start seeing gas build-up in the storage tank.

- You can test it by lighting a small flame (safely, of course!).

Use Your Biogas!

- Connect the stored gas to a simple stove using a tube.

- Enjoy free cooking fuel from your own food waste!

Tips for Best Results

- Keep your system in a warm place (bacteria work best at around 30-40°C).

- Stir the mixture occasionally to help the digestion process.

- Don’t overfill the digester—give the bacteria time to do their job!

- Use the liquid digestate as fertilizer for your garden or crops.

Why Build a DIY Biogas System?

- Free, renewable energy – No more wasting food, turn it into fuel instead!

- Eco-friendly – Reduces methane emissions from food waste in landfills.

- Low cost – Most materials are cheap or easily available.

- Sustainable waste disposal – A great way to manage organic waste.

- Produces natural fertilizer – Your plants will love it!

Final Thoughts

Setting up a DIY biogas system may sound complex, but once you get started, it’s an easy and rewarding process. Imagine cooking a meal using energy made from last night’s leftovers—that’s sustainability in action! Whether you want to reduce waste, save money, or explore renewable energy, a small-scale biogas digester is a fun and practical project to try.

If you found this guide helpful, share it with others who might be interested in turning their food waste into free energy. Got questions or experiences to share? Drop a comment below—I’d love to hear from you!