| What is inside? Table of contents of Complete Biogas Handbook is as below: | ||||||||

| I: Overviews | ||||||||

| 1: This Book | 2 | |||||||

| 2: Energy | 5 | |||||||

| 3: Math | 10 | |||||||

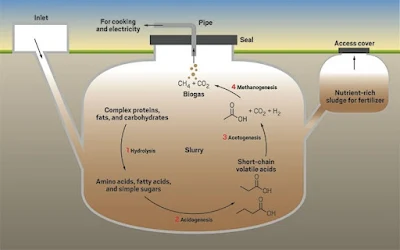

| 4: Biology | 14 | |||||||

| II: Parameters | 23 | |||||||

| 5: The Airless World | 24 | |||||||

| 6: TS, VS, FS | 25 | |||||||

| 7: pH | 26 | |||||||

| 8: Temperature | 31 | |||||||

| 9: C/N | 35 | |||||||

| 10: Percentage of H2O | 46 | |||||||

| 11: HRT and Loading Rate | 50 | |||||||

| 12: Agitation | 52 | |||||||

| 13: Toxins | 53 | |||||||

| 14: Pressure and Surface Area | 56 | |||||||

| III: Substrates | 58 | |||||||

| 15: Purified Substances | 59 | |||||||

| 16: Manure Substrates | 65 | |||||||

| 17: Plant Substrates | 73 | |||||||

| 18: On Growing Substrates | 80 | |||||||

| IV: Uses | 85 | |||||||

| 19: Scrubbing | 86 | |||||||

| 20: Combustion | 94 | |||||||

| 21: Illumination | 97 | |||||||

| 22: Burner Design | 101 | |||||||

| 23: Cooking | 103 | |||||||

| 24: Water Heating | 104 | |||||||

| 25: Steam | 110 | |||||||

| 26: Refrigeration | 112 | |||||||

| 27: Engines | 113 | |||||||

| 28: Space Heating | 121 | |||||||

| 29: Gas Requirements | 125 | |||||||

| V: Troubleshooting | 128 | |||||||

| 30: Cultures | 129 | |||||||

| 31: Startup | 131 | |||||||

| 32: Scum | 133 | |||||||

| 33: Foaming | 137 | |||||||

| 34: Sediment | 138 | |||||||

| VI: Design | 139 | |||||||

| 35: Basic Generator Types | 140 | |||||||

| 36: Heating Generators | 143 | |||||||

| 37: Agitation | 153 | |||||||

| 38: Gas Handling | 157 | |||||||

| 39: Slurry and Effluent Handling | 161 | |||||||

| 40: Pumping | 163 | |||||||

| 41: Construction Materials | 167 | |||||||

| 42: Sizing Generators | 169 | |||||||

| 43: Safety | 173 | |||||||

| 44: Economics | 176 | |||||||

| 45: Design Process | 181 | |||||||

| VII: Plans | 186 | |||||||

| 46: Pipes and Drums | 187 | |||||||

| 47: Test Generator | 197 | |||||||

| 48: Modular Batch Generator | 200 | |||||||

| 49: Hybrid Generator | 203 | |||||||

| 50: Home Wastes Generator | 208 | |||||||

| 51: Continuous-Fed Fibrous Substrates Generator | 211 | |||||||

| VIII: Appendices | 213 | |||||||

| Appendix 1: Analysis | 213 | |||||||

| Appendix 2: Biohydrogen | 217 | |||||||

| Appendix 3: Agricultural Use of Effluent | 219 | |||||||

| Appendix 4: Math of Gas Production | 223 | |||||||

| Appendix 5: Specific Gravity | 227 | |||||||

| Appendix 6: Drill Statistics | 228 | |||||||

| Appendix 7: Burner Design | 231 | |||||||

| Appendix 8: Vital Statistics of Gases | 233 | |||||||

| Appendix 9: K and C Values | 235 | |||||||

| Appendix 10: Steam Temperature, Pressure, Water Depth | 237 | |||||||

| Appendix 11: Heat Transfer in Pipes | 238 | |||||||

| Appendix 12: Decimals and Fractions | 241 | |||||||

| Appendix 13: Geometry, Trig | 243 | |||||||

| Appendix 14: Metric Conversion | 245 | |||||||

| Appendix 15: A Simple Method for Temperature Conversion | 248 | |||||||

| Appendix 16: Terms | 249 | |||||||

| Appendix 17: The Answers | 253 | |||||||

| Appendix 18: Bibliography | 259 | |||||||

| Appendix 19: Author’s Afterword | 270 | |||||||

| Appendix 20: Contents, Figures, and Tables | 272 | |||||||

| Appendix 21: Index and Authors | 283 | |||||||

Search This Blog

Sunday, August 22, 2021

Friday, April 17, 2020

Design and construction of mini biogas digester for family use

The biogas digester is composed of a green house made with hollow sunlight sheet and metal supporting frame, a membrane digester with a gas storage bag combined in one, a stainless steel sink, a stainless steel outlet, a biogas filter and a biogas booster pump:

1. Biogas production of 2m3/day is good enough for a family

2. It is a DIY kit small scale biogas system for convenient transport and easy assembly.

3. It is surface mounted, there is no need for digging or heavy construction.

4. It can be assembled within 2 hours by anyone with manual and video guidance.

5. Treated organic waste locally, use biogas for cooking, electricity or feed garden with nutritious liquid fertilizer.

6. Used for family, farm, restaurant, hotel, resort to treat organic waste, such as food waste, sewage sludge, animal waste.

7. Light weight and easy to install, packed in carton box.

8. Life span more than 10 years - made of stainless steel frame

9. Raw material of green house and PVC biogas storage bag

10. Specification 156*120*195cm

11. Methane Content 65% which is excellent for cooking

1. Biogas production of 2m3/day is good enough for a family

2. It is a DIY kit small scale biogas system for convenient transport and easy assembly.

3. It is surface mounted, there is no need for digging or heavy construction.

4. It can be assembled within 2 hours by anyone with manual and video guidance.

5. Treated organic waste locally, use biogas for cooking, electricity or feed garden with nutritious liquid fertilizer.

6. Used for family, farm, restaurant, hotel, resort to treat organic waste, such as food waste, sewage sludge, animal waste.

7. Light weight and easy to install, packed in carton box.

8. Life span more than 10 years - made of stainless steel frame

9. Raw material of green house and PVC biogas storage bag

10. Specification 156*120*195cm

11. Methane Content 65% which is excellent for cooking

- Construction video:

DIY kit assemble mini biogas digester for family use

Need Biogas Now?

Thursday, April 2, 2020

Calculation of feeding ratio for 1000 liter biogas digester

To my

understanding 1000 liter/40 = 25 liter. So it is advisable to feed 25

liter of food waste mixed with water. It means, your food waste is

already included in that 25 liter. I have read from this elsewhere, the

maximum ratio of food waste to water

you can apply is 1:1 (though to me its too much for the microbes to

handle). Roughly the maximum weight of food waste you can put is 12.5 kg

in which you add another half of water to add up to 25 liter as total

mixed. However its up to you what level of total solids you want to

practice by reducing the food waste within that 25 liter. The more

effluent you take out from the digester, the more bacteria you will

discard and that may affect whole digestion process and becoming slower

in producing gas.

Need Biogas Now?

Saturday, March 28, 2020

Construction of 45 liter biogas biodigester for beginner

To construct a simple biogas digester in the photo above is easy. The materials you need are readily available at any hardware store near your residential area.

Basically the system consist of:

1. Inoculum

2. Biogas biodigester

3. Biogas storage

4. Connection between biodigester and its biogas storage

Inoculum

Inoculum is a starter for the anerobic fermentation process to begin. It consist of consortium of microbes to help in digesting suitable raw material and able to turn them into biogas and effluent that is more environment friendly within a short period of time compared to conventional aerobic composting.

Biodigester

What is a biodigester? The function is to contain the fermentation process of food waste occurred in an aerobic condition without any oxygen.

Biogas storage

Used tyre tube to contain and store biogas produced from the fermentation.

Connector

A silicon clear host to connect gas produced from biodigester to the storage bag.

Other accessories and materials needed

PVC pipe, silicon gel, plastic and metal valve, etc.

Want to construct your own low cost biogas biodigester ? CLICK HERE!

Basically the system consist of:

1. Inoculum

2. Biogas biodigester

3. Biogas storage

4. Connection between biodigester and its biogas storage

Inoculum

Inoculum is a starter for the anerobic fermentation process to begin. It consist of consortium of microbes to help in digesting suitable raw material and able to turn them into biogas and effluent that is more environment friendly within a short period of time compared to conventional aerobic composting.

Biodigester

What is a biodigester? The function is to contain the fermentation process of food waste occurred in an aerobic condition without any oxygen.

Biogas storage

Used tyre tube to contain and store biogas produced from the fermentation.

Connector

A silicon clear host to connect gas produced from biodigester to the storage bag.

Other accessories and materials needed

PVC pipe, silicon gel, plastic and metal valve, etc.

Want to construct your own low cost biogas biodigester ? CLICK HERE!

Saturday, February 22, 2020

Inoculum preparation for biogas generation

The most cheapest and easiest way to produce an inoculum is using digestate from working biogas digester. They are consist of active culture with stable activity because consist of varieties of microbes working together or consortium.

Next source is by taking a scoop of slurry or sediment from anaerobic pond. These are also active microbes we can used directly to produce biogas.

If you happen to live nearby cattle farm, dung is another source of microbes that can produce biogas.But to start with cow dung we need to mix it with water and ferment until it mature in which produces biogas.

Do not mistaken biogas with carbon dioxide. Biogas is flammable while CO2 is not.

So to produce biogas you can start with things that already around you.

Want to construct your own biogas biodigester? Click here!

Next source is by taking a scoop of slurry or sediment from anaerobic pond. These are also active microbes we can used directly to produce biogas.

If you happen to live nearby cattle farm, dung is another source of microbes that can produce biogas.But to start with cow dung we need to mix it with water and ferment until it mature in which produces biogas.

Do not mistaken biogas with carbon dioxide. Biogas is flammable while CO2 is not.

So to produce biogas you can start with things that already around you.

HRT - hydraulic retention time is period taken for a waste to be digested to produce biogas completely at particular temperature

I am very lucky able to find old air temperature data at my place. The average is like 26.8 celcius. So, according to David David William House

's graph, the approximate HRT is 45 days. So, it is safer for me to

decide to choose 50 days HRT for my digester. To determine how much to

feed daily is by calculating = digester volume (liter) / HRT (day) = 200

liter/50 days = 4 liter/day. Again, rule of thumb do not get solid food

waste over 50% of daily feeding volume. In my case for 4 liter feeding,

2 kg of food waste is the maximum volume then mix with 2 liter of water

to a total of 4 liter. If you do not have confident and do not want to

get your system sour lets try less than 50% food waste of your daily

feeding volume. Please try and error, experiment with your system and

you will learn a lot finding the most optimum condition to run your

system.

Want to construct your own biogas biodigester? Click here!

Low cost biogas digester design and lay out

I have always think of ways to recycle my kitchen wastes. Living in housing area with limited backyard space unable me to dig appropriate hole to bury all my kitchen waste without leaving smelly odor. I don't have any experience composting and food waste easily become smelly if you do not handle them properly. Then I came across anaerobic composting which is enclosed and used cow dung as starter. I feel this technique is practical and easy to construct. To make it interesting, I want to use a modified garbage bin and call it food waste recycle garbage bin just like when you throw your usual wastes into a dustbin but mine is a little bit different in which it can recycle organic wastes. That's how I came up with the idea.

Its not really difficult. Take a normal standard garbage bin at modified it a bit by installing inlet for feeding, outlet port for effluent and outlet valve for biogas to be collected into a tyre tube. Its that simple.

Then I built bigger module have an upgrade experience from my first biodigester as above. The new digester is 160 liter and connected to 500 liter biogas bag as storage. I also found how to modify a normal burner into a biogas burner.

Now I convinced that biogas generated at home really can be used for cooking.

Need Biogas Now?

How to make biogas at home manual by David William House is worth to try (Recommended)

The first edition of the book quickly established itself as the book on

biogas generation. Now in a newly revised edition, David House brings

together all the information, from the most theoretical scientific

research to grass roots homescale trial and error.Here are the

detailed designs for generators and the knowledge, encouragement,

imagination, and humor you will need to build a generator of your own.

While biogas may not yet be a household word, you should consider it

seriously if you believe in the future of alternative energy.

Use biogas for illumination, cooking, water heating, refrigeration, space heating, and to fuel vehicles.

*Over 100 figures and tables

*All the necessary formulas

*6 model generators and a design flow chart

*Complete list of resources

*Extensive bibliography

.

Wednesday, March 12, 2014

Thursday, March 6, 2014

The uses and equivalent of biogas

1 cubic meter of biogas is equal to:

Illumination equaling that of a 60-100 watt bulb for 6 hours.

5.2 kg of CCl4 (Carbon tetrachloride)

0.7 kg petrol

can run a 1 horse-power motor for 2 hours

can generate 1.25 k electricity

can drive a 3-tonne lorry 2.8 km

can cook 3 meals for a family of 5-6

Illumination equaling that of a 60-100 watt bulb for 6 hours.

5.2 kg of CCl4 (Carbon tetrachloride)

0.7 kg petrol

can run a 1 horse-power motor for 2 hours

can generate 1.25 k electricity

can drive a 3-tonne lorry 2.8 km

can cook 3 meals for a family of 5-6

ARTI Style Methane Generator System

It really is just two plastic barrels, one inverted inside the other, with three pipes -- one to get the food in, one to take the liquid fertilizer out and one at the top to deliver the gas to your cookstove or generator. 1000 liter tanks should get you about 2 hours of cooking gas a day if you live in a warm climate.

Cows eat food, not manure, and the bacteria in the cows stomach and intestines also eat that food, mixed with saliva and water. The goal is to replicate the inside of a cow's digestive tract to help the bacteria get the most energy from the food.

We only use the dung/manure to"innoculate" the system on the first day because it is the easiest non-invasive way of getting the "bacterial biogas experts" out of the animals' guts and into the tank.

In many respects making biogas is similar to making yoghurt. If you have a friend who has an active culture of methanogens from their own biogas digester (or from a septic tank, or from their baby's diaper just put them in. If you don't use manure, however, I'm not sure what or how much to feed them in the beginning.

Start up:

- The process working with mesophils from animal dung, however, is started very simply by taking about 40 or 50 kg (maybe 4 to 6 10 or 15 liter buckets) of manure (we used horse manure in Germany, cow manure in Egypt, but any manure will do) and mix it into the bottom container with water (this is per 200 liters of water but we just go ahead and fill the whole thing even up to a 1000 liters of water; it may make the wait time for first flammable gas a bit longer as it takes the bacteria time to reproduce and fill that volume, but it worked fine for us as we didn't want to haul in more manure.). Then put the top barrel on and open the top valve so all the air escapes and the top barrel sinks down into the bottom barrel all the way.

- You then close the valve at the top so no air can get in and just let it sit there for anywhere from 2 weeks to a month (depending on climate). During this boring period the bacteria will multiply. At first they will just produce CO2. After a few weeks open the valve and flame test with a candle (we didn't use a flashback arrestor! Doh! :) ) . The first couple of times the escaping gas will blow out the candle. Eventually, after a few days, the methane content will exceed 50%.

- Once the gas starts to burn you can start feeding your digester ground up food waste (mixed in a blender with water, about 1 to 2 Kg a day, but start slowly so as not to overwhelm the bacteria; start with 200 grams then 400 the next day etc.). Soon the CH4 content at the top of the tank will exceed 60% (since CO2 is water soluble it can get up to 70%) and can be directly used in cook stoves and engines. Hope that helps explain it. It works well and is fairly simple you'll find. Give it a try !

Remember you only have to put the manure in THE VERY FIRST DAY. After this no more manure is needed.

The current process of biomethanation, which uses feedstocks like cattle dung, human feces, distillery effluents etc. is highly inefficient, because the nutritionally available calories and nutritive value of those substances is quite low.

ARTI developed in 2003 a new biogas technology which uses high calorie feedstock, consisting of starchy or sugary material. This material is capable of producing about 250 kg of methane per ton of feedstock (on a dry weight basis) and the reaction takes only 1 day to complete. In the case of a household biogas system, application of daily just 1 kg of feedstock is enough to provide a family with sufficient biogas to cook all the meals. The material that can be used as feedstock in the new biogas system consists of waste grain, seed of any plant species, oilcake of non-edible oilseeds as well as nonmarketable or nonedible fruits (wild species of ficus, overripe mango and banana). Even the flour mill can be used as feedstock.

Read full story here: http://solarcities.blogspot.com/2009/09/animation-of-simple-telescoping-biogas.html

Need Biogas Now?

Biogas fuel without end

Biodigester in a glasshouse to maintain the temperature.

The glasshouse temperature reach 20 degree celcius.

Biogas is safe(?)

Blue flame from methane biodigester.

Full story: http://solarcities.blogspot.de/2012/12/fuel-without-end-amen.html

Want to construct your own biogas biodigester? Click here!

Want to construct your own biogas biodigester? Click here!

Need Biogas Now?

Subscribe to:

Comments (Atom)